CLS continues to make improvements to increase efficiencies, improve safety for our Team Members, and provide a better quality product to our Customers.

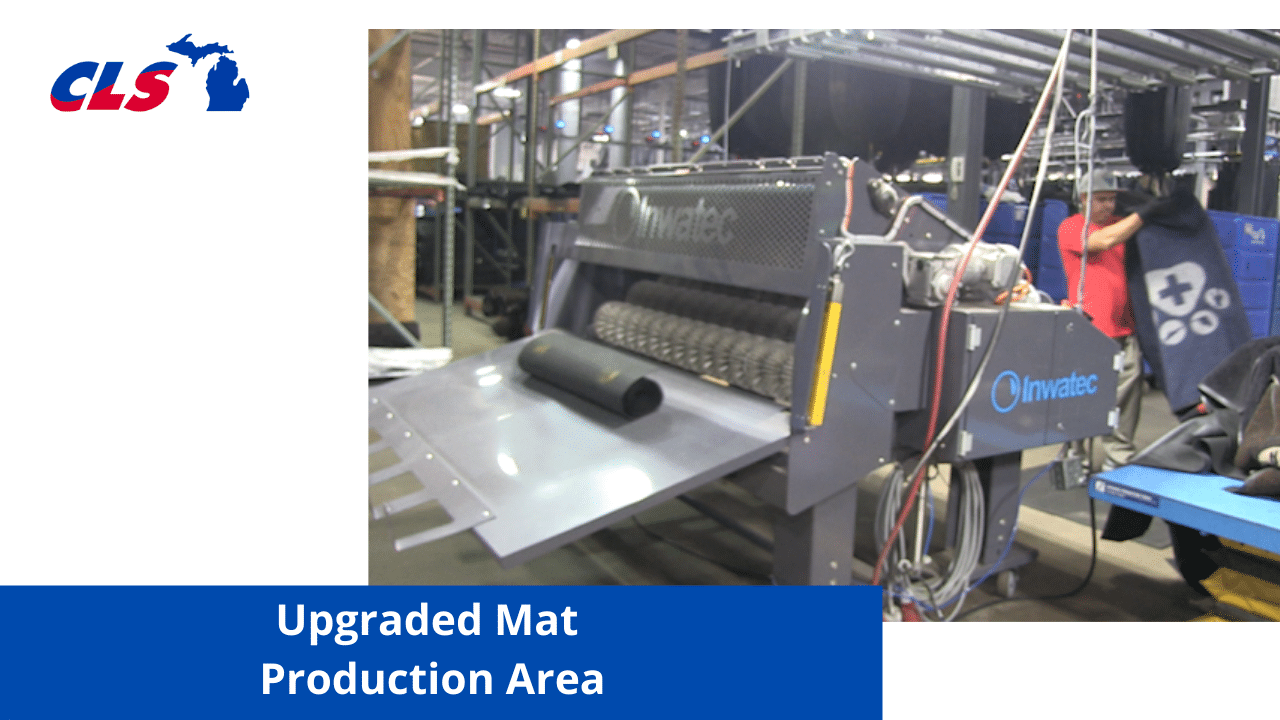

We completely redesigned our Mat Department in 2021.

The new conveyors take the clean mats from the dryers and drop them into slings that are lifted overhead. The overhead rail system delivers the slings of clean mats to a drop table automatically.

“We’re pushing out more mats per day. And it’s a lot easier. It’s less stress on the back” said CLS Production Supervisor, Errick Hutson.

The clean mats are then dropped onto a lift table. Our Team Members use a machine to roll each mat and then sort them by size and color.

The upgrades to our Mat Department have made the process of producing mats much easier for our Team Members.

“It’s a lot easier because you don’t have to keep moving bags around. They automatically come” said Hutson. “We can lower the table to where we need it to be comfortable, so we’re not bending down so far. For some people the table may have been too high, for some it may have been too low.”

Now the process is much safer and efficient.

And improvements like this mean a lot to our CLS Team Members.

“It shows that they care about us. It shows that they saw the struggle of the old way. Now that they’re improving to make it better for us, to keep employees here, 11 years like I am, or longer” said Hutson.