Ever wonder what happens to the laundry we pick up from our customers from all over the state each week?

CLS is in the middle of a seven-million dollar project to transform how we deliver the image of our customers. Phase one is now complete and it’s already making a huge difference.

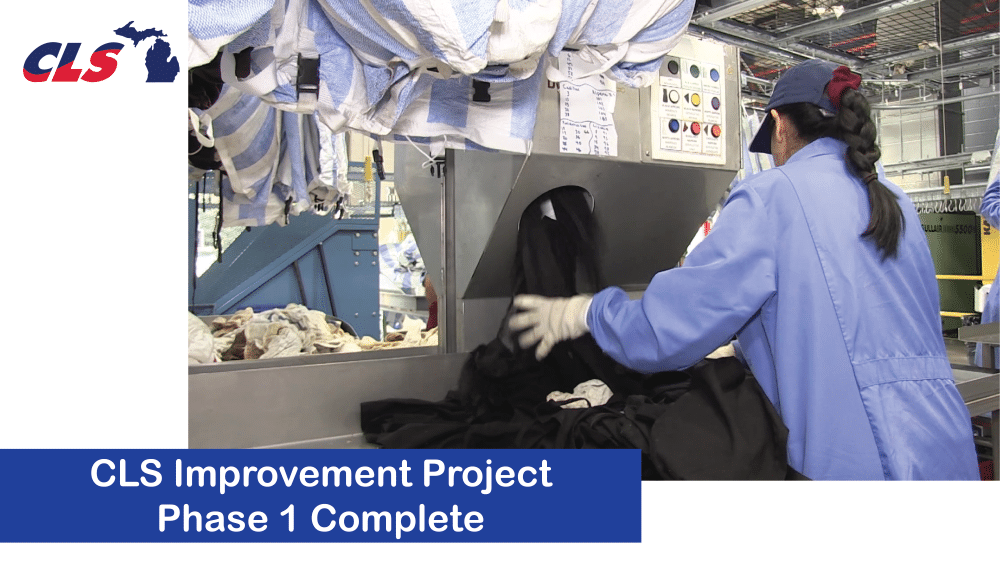

The process starts with the customer storage bags that come in from all over Michigan. A trolley system now moves the bags around, making it easier for our team members.

It’s a lot less manual labor than it used to be of pulling the bags down with a hook, said Scott Chenevare, CLS Assistant Production Operations Manager.

The trolleys take the laundry to the sorting tables, where our eight most used products get sorted by team members through suction tubes. The items are sent straight to the wash aisle to be cleaned faster. This helps get the products back out to our customers quicker.

The items that do not go through the suction tubes move up a conveyor belt to another level, where they are sorted into bins with similar items and weighed to make sure they’re even. The automated sorting process and exact measurements will help maintain our equipment and our goals of being green.

We want to make sure we are optimizing our space in the washers so that we’re not wasting water, chemistry, and we’re washing to our fullest ability, said Chenevare.

Once the items are sorted, they keep moving toward the washing machines. The new automated system helps us know what’s inside each sling at all times and what products are waiting to be washed.

The system automatically tells itself that there are two that go together and it’ll automatically pair and then it will send it to storage for the wash aisle automatically, so we don’t have to do that any more, said Chenevare.

In all, it’s a better process for our team and CLS customers.

It’s definitely been a lot easier to manage since it’s more automated than it is physical labor, said Chenevare. It’s very exciting. Not just for me, but for everybody. Even sales and service, they can say that our production facility is upgrading and it’s only going to get better. It’s better for our customers.”

And this is just the phase one of three in the process to make CLS more efficient, safe and sustainable.

To find out how CLS can help deliver your image click here for a quote today.